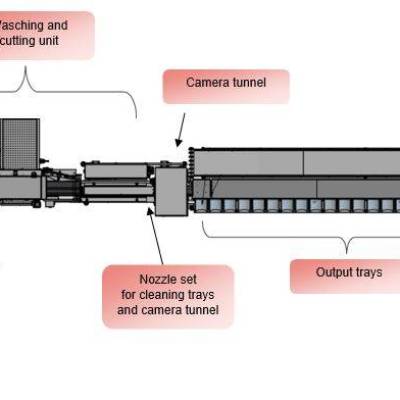

for washing, cutting and sorting white and green asparagus

-

Image gallery: Watch video

-

Sorting machine AUTOSELECT Standard

ATS STAN 12+1 ATS STAN 15+1 ATS STAN 18+1 ATS STAN 21+1 ATS STAN 24+1 ATS STAN 27+1 ATS STAN 30+1 Output trays 12+1 15+1 18+1 21+1 24+1 27+1 30+1 Output tray width approx. 300 mm 300 mm 300 mm 300 mm 300 mm 300 mm 300 mm Distance between turnouts approx. 300 mm 300 mm 300 mm 300 mm 300 mm 300 mm 300 mm Total length approx. 11500 mm 12400 mm 13300 mm 14200 mm 15100 mm 16000 mm 16900 mm Spears* per h approx. 35000 35000 35000 35000 35000 35000 35000 Sorting machine AUTOSELECT Kompakt

ATS Kom 12+1 ATS Kom 15+1 ATS Kom 18+1 ATS Kom 21+1 ATS Kom 24+1 ATS Kom 27+1 ATS Kom 30+1 Output trays 12+1 15+1 18+1 21+1 24+1 27+1 30+1 Output tray width approx. 200 mm 200 mm 200 mm 200 mm 200 mm 200 mm 200 mm Distance between turnouts approx. 200 mm 200 mm 200 mm 200 mm 200 mm 200 mm 200 mm Total length approx. 10170 mm 10600 mm 11030 mm 11460 mm 11890 mm 12320 mm 12750 mm Spears* per h approx. 35000 35000 35000 35000 35000 35000 35000 Sorting machine AUTOSELECT Plus

ATS Plus 12+1 ATS Plus 15+1 ATS Plus 18+1 ATS Plus 21+1 ATS Plus 24+1 ATS Plus 27+1 ATS Plus 30+1 Output trays 12+1 15+1 18+1 21+1 24+1 27+1 30+1 Output tray width approx. 360 mm 360 mm 360 mm 360 mm 360 mm 360 mm 360 mm Distance between turnouts approx. 360 mm 360 mm 360 mm 360 mm 360 mm 360 mm 360 mm Total length approx. 12220 mm 13300 mm 14380 mm 15460 mm 16540 mm 17620 mm 18700 mm Spears* per h approx. 35000 35000 35000 35000 35000 35000 35000 *white asparagus

-

Basic equipment:

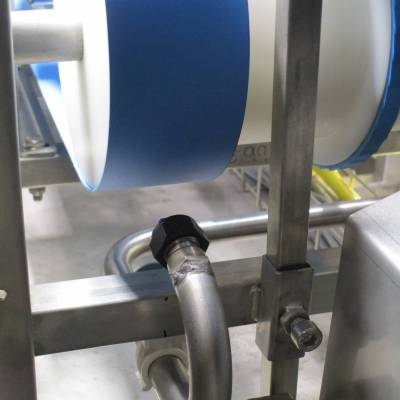

- Washing and cutting unit including recycling tank made of stainless steel

= no corrosion, even during longer standstills

consists of :

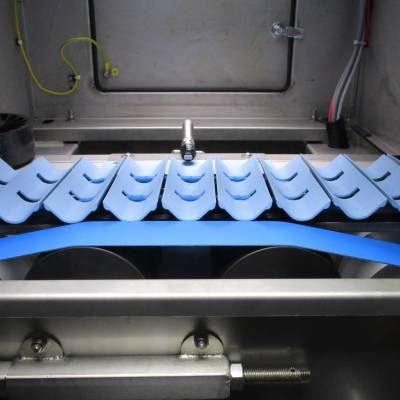

Mesh belt for placing the asparagus spears

Head and foot bands for aligning the spears

Blade for cutting spears to required length

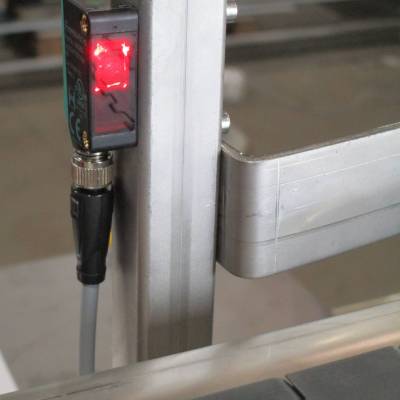

Sensor control

Pump (different variants depending on requirement)

Recycling tank with 2 sieving levels (coarse and fine filter)

Cleaning of the complete asparagus spear with different nozzle sets, controlled by a solenoid valve:

1st step: with recycled water from the recycling tank

2nd step: with fresh water

= improved cleaning possibility – less fresh water consumption - Camera tunnel

1. opening option

= for easy cleaning

2. high resolution camera

= improved detection of rust, bloom, etc.

3. LED illumination

= uniform light brightness and colour even with temperature fluctuations

= high luminous efficacy and long service life

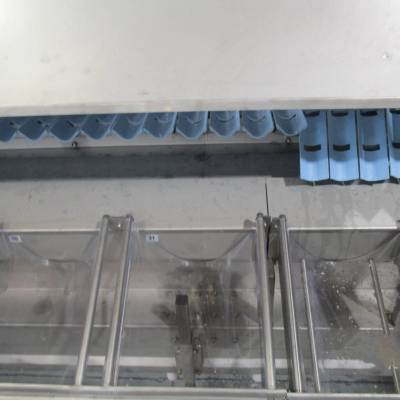

= maximum light intensity immediately when switched on - Output tray

from 6 output trays upwards (Width variably adaptable to box widths)

particularly ergonomic design

made of easy-to-clean PE material

= Minimisation of asparagus breakage

compact low-noise turnouts (different distances possible) - Evaluation tray

Colour: light blue

= Sorting of white and green asparagus possible with one machine - Galvanised + powder-coated switch cabinet (IP 66)

= Main control - Evaluation software specially developed by Hermeler

simple, fast data entry via scanner or transponder

Data storage and printout possible

Storage of different parameter sets, retrievable at any time

Programming of any number of punches or fields possible - Nozzle set for cleaning the evaluation trays and the camera tunnel

Additional fresh water is sprayed into the areas of evaluation (upper head plate, lower belt, evaluation trays).

= increased evaluation quality - Table made of stainless steel

for placing the asparagus spears

INDIVIDUALLY CONFIGURABLE

- Feeding belt

consists of two different belts:

1. Placement belt.

2. Vibrating belt:

for automatic alignment of the spears with “foot end down”.

Sensor between the vibrating belt and the washing and cutting unit causes 90% occupancy of the evaluation trays

Different belt lengths and other variants of placement belts available, e.g. cleated belt especially for green asparagus, head or foot belt without vibrating function, etc. - Conveyor belt

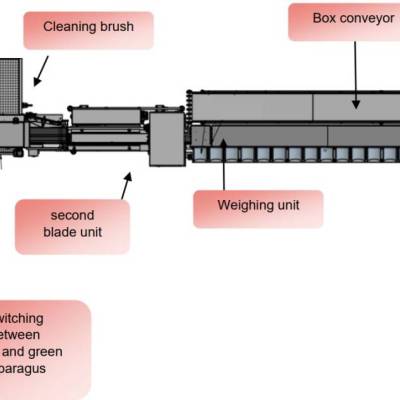

for the removal of asparagus cuttings - Switching between white and green asparagus

equipped with two different nozzle blocks

only the lower part of the green asparagus is cleaned by switching off a nozzle block

Water pressure adjustment by the control system

= no water in the green asparagus head - Second blade unit after cleaning for a precise, final cut

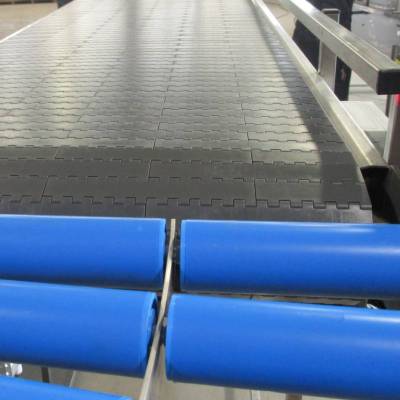

- Box conveyor sensor-assisted

consisting of:

a stainless steel frame construction

a plate band (plastic chain) - Roller conveyor with or without curve for further transport of the boxes, e.g. to a flow cooler

- Adaptation to structural conditions by means of

- Curve 90° or 180

- Running direction right or left possible

- a wide range of feeder and conveyor belts for efficient operating sequences

- Output tray width from approx. 180 mm, adapted to the box size

- different sorts at one output tray or distribution of one sort over several output trays

- Weighing unit

- Barcode scanner

- Cleaning brush for the evaluation trays

- Water basin for boxes with unsorted asparagus

for easier placement of the asparagus spears on the feeding belt / table - Construction of sorting machine for other types of fruits and vegetables

Individual modifications regarding equipment, dimensions, etc. on request are possible

- Washing and cutting unit including recycling tank made of stainless steel